Vertical Falling Film Evaporator

|

The process fluid to be vaporized is feed to

the evaporator at the top of the tube sheet. A suitable distribution unit

is nessecary in order to achieve an even liquid distribution. It is

paramount the for this process minimal wetting rate is achieved.

In general the process liquid flows at the tue inside. But there are also applications where the liquid is applied on the tube outside. Due to gravity the liquid forms a continious liquid film with hydrodynamic characteristics which are determined by the Fil Reynods and Kapitza number. In general steam is used as a heating source. The steam condenses on the tube outside of the tube and flows also gravity controlled to the bottom of the unit Inside the tubes the two phase flow is separated by means of a separator at the bottom of the unit. |

In multieffect falling film evaporators the vapour produced is used in order to heat a so called second effect on a lower temperature and pressure level. This is possible due to the very low required meant temperature difference between heating medium and process liquid. In seawater desalination up to 12 effects are possible in order to evapoate most efficently

|

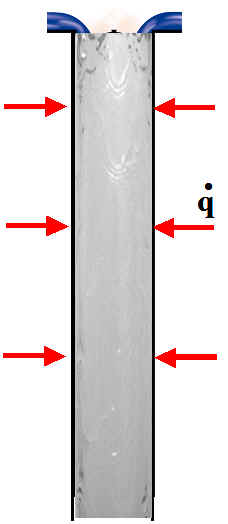

In the picture on the left side it is

shown how the heat e.g. by means of condensation, is transfered

through the wall to the process liquid to be evapoarated.

|

Horizontal film evaporator

In case of horizontal film evaporation the liquid to be vaporised is distributed evenly on the top of a horizontal tube bundle. For this purpose perforated plates and special designed jet nozzles are applied. A minimum recirculation rate is required in order to maintain a minimum wetting rate. The liquid chraracteristics between the tubes are determined by the Film reynods number and Kapitza number. The fluid can be encounter between the tubes as droplets, jet or continious sheet. Due to the liquid imingment the heat transfer in horizontal units is in general higher compared to vertical evaporators